This case study summarises the outcomes from an audit conducted on a large feedlot with an energy consumption of 3,000,000 kWh at an annual cost of $350,000, resulting in emissions of 2,850 tCO2-e per year. Energy and emission savings have been estimated to be 21% and cost savings at around 26%.

Summary

A specialist feedlot averaging 1.5 cycles per year feeding cattle with wheat, barley, sorghum grain and quality roughages could benefit from a recent energy savers audit. The site has its own feed mill, processing wheat and barley and steam flaked grain onsite, which enhances the efficiency of utilisation leading to increases in meat and milk production while providing a positive environmental impact in terms of odour abatement. Manure is removed in between the cycles and used to produce compost, generating another stream of income.

The site energy consumption currently consists of:

- Four pumps ranging from 2.2 kW to 30 kW supply water from creeks and bores to the feedlot site

- Mill intake equipment

- Grain preparation and cleaning machinery

- Grain steam flaking equipment

- Various belt and screw conveyors

- Two LPG fired boilers for steam production

Water is used for both the steam and milling process, drinking water for cattle, and services on site. Water is supplied by two bores, with each each delivery system consisting of one pump, pumping water to a storage then gravity fed to the end use. The main system consists of a borehole pump, which pumps the water from the borehole to the dam, the second system a centrifugal pump, which pumps water to storage while another submersible pump delivers water for the services onsite. The last system assessed consists of a borehole pump, which pumps water to a storage tank. A Reverse Osmosis (RO) system treats the bore water to remove the salt in the water. The water is used to produce steam using a “fire-tube” and a separate “water-tube” boiler for the conditioning of the grains and to keep the palm oil at 60°C.

The onsite milling process involves:

- Intake and Storage- unloading the vehicles and transferring the product to the storage system.

- Cleaning–keeping the feed produced consistent, hygienic and to the highest quality. After cleaning the grains are stored in silos until needed then delivered to four weigh hoppers.

- Steam flaking–using live steam to increase the temperature and moisture level, then flaked between large diameter rolls. The cooking process is obtained in steam chambers which is added into the chambers at different vertical levels.

- Out Loading–the flakes are delivered to a storage building using conveyors. From storage the flakes are loaded on mixing trucks where they are mixed with molasses, palm oil and vitamins which are stored in tanks, before being delivered to the cattle. The palm oil is heated using steam, to approximately 60 °C to keep the oil in its liquid phase.

The two connected electricity accounts consumed over 380,000 kWh of electricity at a cost of over $120,000 with over 9,400 GJ of LPG used at a cost of approximately $230,000. Converting gas (1 GJ = 277.77kWh), a total over 3,000,000kWh at a cost of approximately $350,000 was consumed, to improve efficiency the energy audit recommended a number of measures listed at Table 1.

Table 1. Audit Recommendation and Resulting Savings.

|

Recommendation |

Energy Savings (kWh) | Cost Savings ($) | Payback Period (Year) | Emission Savings (tCO2-e) |

Capital Cost ($) |

|

Install Variable Speed Drive (VSD) in two pumps |

5,285

(0.1%) |

2,339 | 2.7 | 4.8 |

6,362 |

|

Exhaust Economiser |

115,500

(4%) |

10,186 | 3.4 | 105.8 |

35,000 |

|

Cogeneration Plant |

451,383

(15%) |

57,651 | 5.7 | 415 |

330,000 |

|

Install 30kW Solar PV |

49,008

(2%) |

22,691 | 3.0 | 45 |

67,923 |

|

Total |

621,176

(21%) |

92,867 | Avg 4.7 | 570.6 |

439,285 |

Due to the design of the irrigation system the required flow rate from the pumps varies. The pumps are currently being throttled back to meet the system requirements, to alleviate this, the installation of a VSD in two of the pumps (2.2 kW submersible and 7.5 kW bore) will reduce energy consumption by 5,285kWh and provide a payback of 2.7years.

Implementation of exhaust economizer on the fire tube boiler

In a typical boiler system, 10% to 20% of energy input is lost with the hot exhaust gas escaping to the atmosphere. Recovery of the hot exhaust gas using an exhaust economiser, a heat exchange device that can preheat the feed water. Studies show that a 5-10% reduction in fuel use by the boiler can be achieved from these systems. For this recommendation, a conservative 54% of energy reduction has been used which could lead to around 115,000kWh being saved and 105.8 tCO2-e per annum avoided.

Implementation of a Combined Heat and Power (CHP) system

Using LPG could partially offset the amount of electricity bought from the grid, preheat the feed in water for the steam boilers and maintain the palm oil above its solidification temperature. A cogeneration system is comprised of two basic parts: a power generator and a heat recovery system, for this feedlot two options have been assessed:

- Gas turbine– available across a wide range of power from a few kilowatts to utility-sized units larger than 300 MW for operation in combined-cycle power plant.

- Gas Reciprocating engine– to drive electricity generators with heat exchangers recovering waste heat in hot water.

Utilising the exhaust energy from gas turbines, useful hot water or steam can be generated in a heat exchanger. As a result, the overall efficiency of a typical CHP system using a gas turbine can reach 80%. Cogeneration efficiency is always reduced if the heat that can be raised in the recovery system is not utilised with the system sized around the heat requirement. Any imbalance in the energy requirement can then be adjusted by importing from the grid. The heat from a gas engine is available from five areas:

- Engine jacket cooling water

- Engine lubrication oil cooling

- First stage air intake intercooler

- Engine exhaust gases

- Engine generator radiated heat, second stage intercooler

Heat available from areas 1, 2, 3 and 5 is recoverable in the form of hot water, typically on a 70/90°C flow return basis and can be recovered using a plate heat exchanger. The engine exhaust gases which typically leave at between 400 and 500°C can be used directly in a waste heat boiler to generate steam, or via an exhaust gas heat exchanger combining with the heat from the cooling circuits. The amount of heat extraction is usually limited by the allowable stack temperature. A typical lower stack temperature limit is around 130°C to avoid condensation of combustion products in the exhaust system, reducing the risk of corrosion. Combined the cogeneration plant could reduce annual energy consumption by 450,000kWh, costs by over $57,000 and avoid emission of 415 tons of CO2-e per annum.

Biogas and Solar Production

The run-off from the pens is currently sent to a series of lagoons where the organic solids settle. The water at the end of this setting process, which lasts for approximately four or five years, is sprayed to a nearby property with the solids mechanically removed.

The production of biogas was considered using the runoff through an anaerobic process, by covering the lagoon and capturing biogas from the decomposing of organic matter in the effluent. Anaerobic digestion involves the breakdown of organic wastes by bacteria in the absence of oxygen. The generated biogas (a mixture of approximately 50-70% methane, 30-40% carbon dioxide, 1-10% hydrogen, 1-3% nitrogen, 0.1% oxygen, carbon monoxide and hydrogen sulphide) can be used as a fuel, while the residue represents a valuable fertiliser. The methane could then be used in a Combined Heat and Power (CHP) plant, which can produce electricity and heat at the same time.

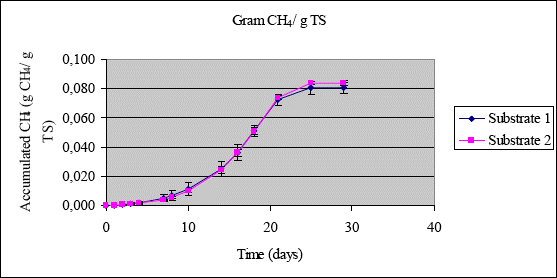

A study from the Rural Industries Research and Development Corporation available HERE, shows that Volatile solids (VS) decline rapidly after excretion. Hence, a significant quantity of methane is lost on the pen surface and this impacts on the economic feasibility of harvesting this energy source. The following can be concluded from manure decomposition.

A study from the Rural Industries Research and Development Corporation available HERE, shows that Volatile solids (VS) decline rapidly after excretion. Hence, a significant quantity of methane is lost on the pen surface and this impacts on the economic feasibility of harvesting this energy source. The following can be concluded from manure decomposition.

- After 20 days a reduction of between 60 and 70% in VS

- After 35 days a reduction of 70% in VS

- After 80-100 days a reduction of 75% in VS

Although digestion of stockpiled manure is still feasible to generate energy, collection of fresh manure is important to maximise output as the rapid decline of VS after excretion impacts on the economic feasibility, with manure needing to be harvested within a few days. Typically, cleaning and removal of manure from one average sized pen (150 head) takes half a day. Hence, there are significant practical implications of implementing a cleaning rotation per pen of less than a week across a large feedlot. To achieve the desired cleaning frequency, equipment (multiple loaders, trucks etc) and labour resources would need to be significantly greater increasing the operation costs, making this opportunity not feasible at this time.

Additionally, the installation of a 30kW solar system on the roof of the storage building could save the site 49,000kWh and over $22,000 per annum.

An energy audit is a good investment

An energy audit is a great first step in moving a business towards a more efficient future by reducing energy use, costs, and carbon emissions onsite. Should the site implement recommendations in the audit then a 21% reduction in energy and emissions will result, with a 26% cost saving.

|

Metric |

Pre-Audit | Post-Audit |

Reduction % |

|

Energy (kWh) |

3,000,000 | 2,390,000 |

21 |

|

Costs ($) |

350,000 | 260,000 |

26 |

|

Emissions (tCO2-e) |

2,800 | 2,200 |

21 |

An energy auditor will review your past energy bills, your equipment and the way your business operates. They’ll show you where you’re using excess energy and explain what you can do about it. Find out about what’s involved in an energy audit HERE.

See our range of agricultural energy efficiency case studies HERE and Subscribe to our bi-monthly energy e-news HERE

If you have any energy efficiency related questions for the team get in touch at energysavers@qff.org.au.

The Energy Savers Plus Extension Program is delivered in by the Queensland Farmers Federation with support and funding from the Queensland Department of Energy and Public Works.